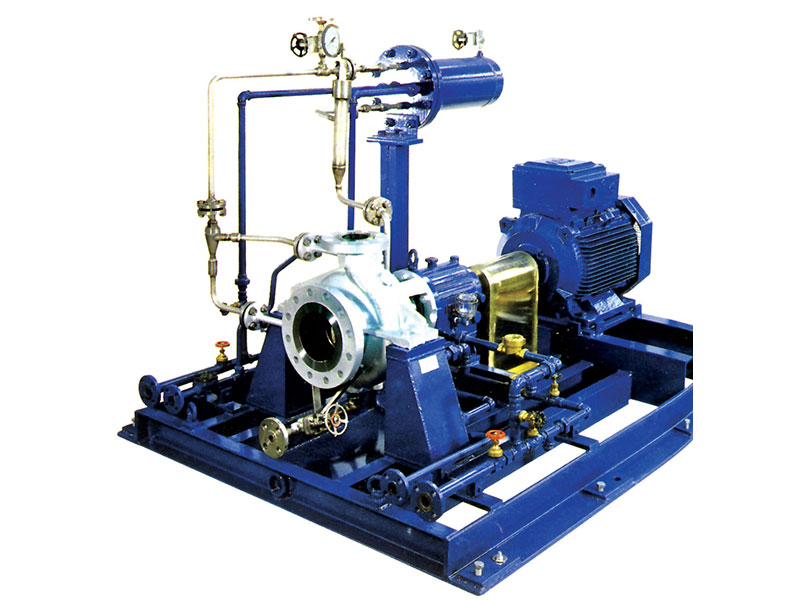

Centrifugal Volute Casing Pumps

Centrifugal Volute Casing Pumps

Models: KP N & C Types

OH1&OH2, API 610 Standard

Material Class:

- Cast Iron

- Cast Steel

- Stainless Steel

- Brass/Bronze alloys

- Duplex alloys

- Acc.to TableH.1(I1…D2)

Application

Liquids

- Petroleum Liquids

- All type of hydrocarbons

- Non-aggressive liquids

- Corrosive Liquids

- Acids

- Brine and alkalis

- Water & sea water

Industrial Usage

- Oil refineries & petrochemical plants

- All processing plants

- Power stations

- Refrigeration Plants

- Condensate

Design & Special Features

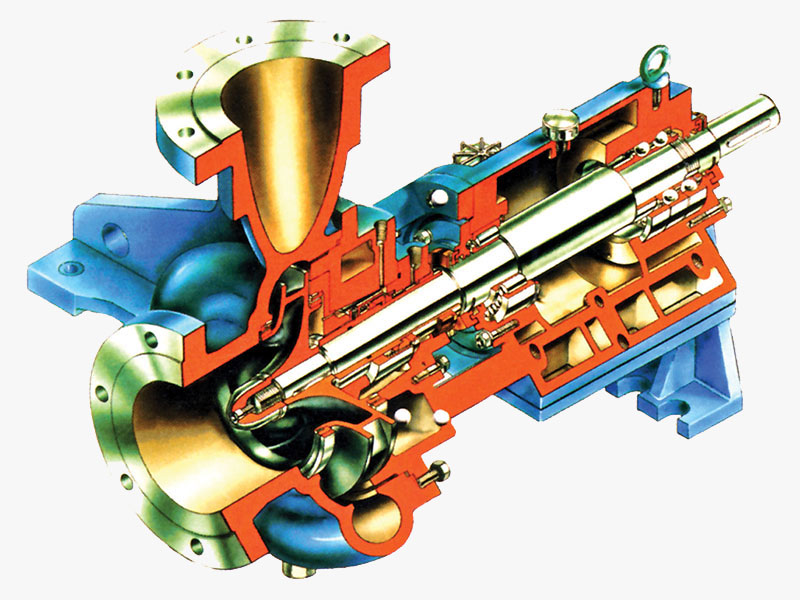

- Horizontal centrifugal single-stage volute casing-End suction

- Design in accordandce with API 610 standard

- “Foot” or “Center line” arrangement

- High hydraulic efficiency

- Low NPSH required

- Easy dismantling of the complete bearing unit towards the drive and

- without the need to disconnect the pump casing from the piping

- No necessity to disconnect the motor if a spacer coupling is used

- Statically/dynamically balanced closed impeller

- Simple, low cost installation

- Long life pumping system

Technical Specifications

| (KP N&C Type) | |

|---|---|

| Nozzle Size | up to 12” |

| Capacity | up to 1500 m3/hr |

| Pressure | up to 15 bar |

| Max. speed | 2950 rpm |

| Max. temperature | 250℃ |

| Max. casing pressure | 40 bar |

| Max. hydrostatic test pressure | 60 bar |

| Sealing | Packing or mechanical seal (acc. to API 682) |

| Design Standard | API 610, Latest edition |

| Flange standard | ANSI (other standards also available) |

| Direction of rotation | Clockwise looking from end motor |

| Drive Mechanism | Direct with flexible/ Rigid spacer coupling |

| Drivers | Explosion proof or standard type (safe area) Electromotor/Diesel Engine |

| Material | According to API 610 Material Code including 316 L, Duplex & Super Duplex |

Price inquiry of pumps manufactured by Kalayepump Company

If you are interested in price inquiry and purchase of the pumps manufactured by Kalayepump Company, you can complete the order form and send it to the sales department.